We interviewed Anders Barlow from the University of Melbourne’s MCFP who has been using Mediaflux to facilitate and evolve the platforms data management.

Arcitecta: For the uninitiated, Nanotechnology might be unfamiliar territory. Can you tell us about yourself and the work that you do?

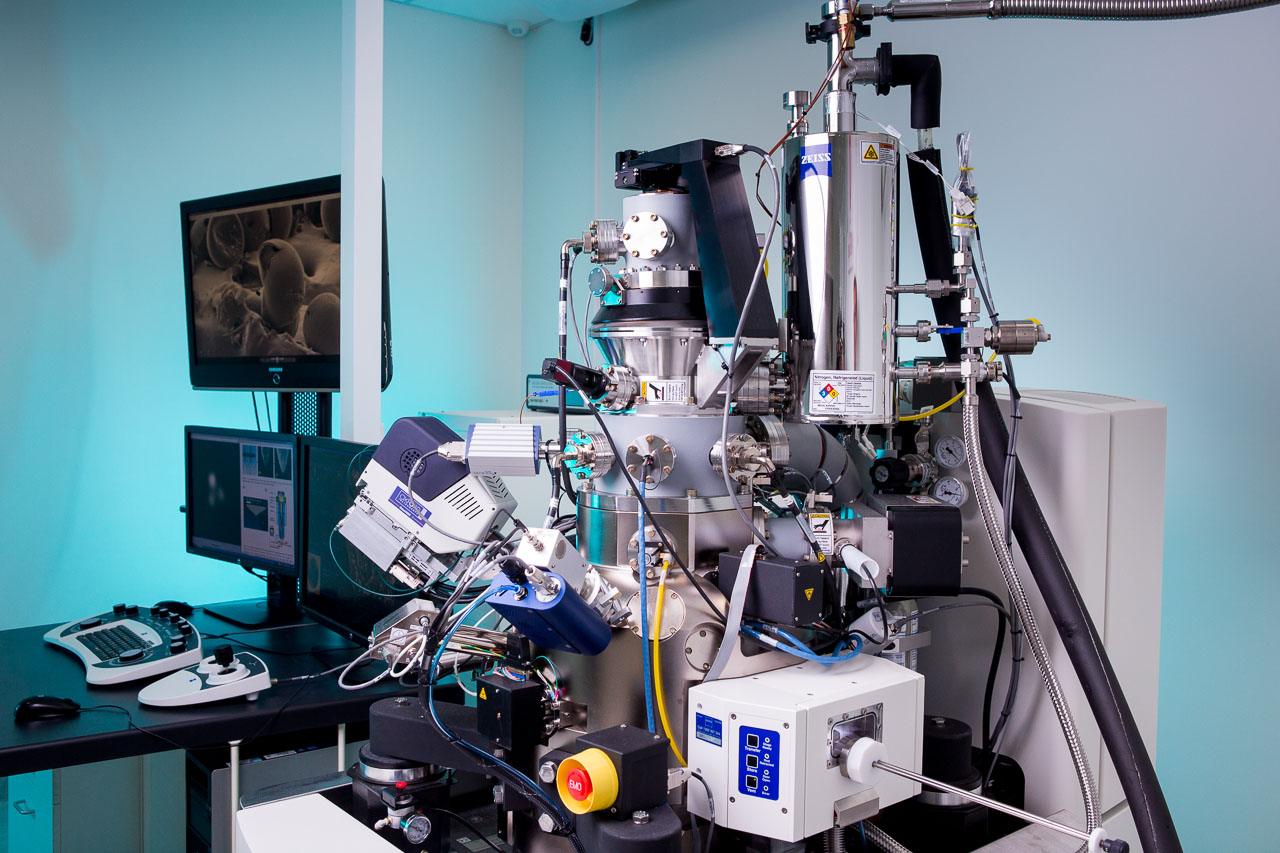

Anders Barlow: I work as an Academic Specialist within the Materials Characterisation and Fabrication Platform (MCFP) at the University of Melbourne where I manage the Helium Ion Microscopy Node.

Much of my background is in the surface analysis of materials with a focus on surface chemical analysis by X-ray photoelectron spectroscopy (XPS), scanning Auger electron microscopy (SAM) and helium ion microscopy (HIM). These fields are brought together in my research, developing our foundation of understanding about the interaction of ion beams with surfaces during chemical analysis and depth profiling, and developing new methods and techniques to leverage these techniques against one another.

Arcitecta: There are a lot of new labs popping up around the University of Melbourne precinct, how do the MCFP work within the greater scientific community?

[AB]: The University of Melbourne has established and supports a very large number of these platforms to bring research expertise and equipment from different areas into one geographical place. Within the MCFP, we have a fairly broad range of expertise, techniques, and instruments available for University of Melbourne researchers, external universities, institutes, and research organisations as well as industry partners.

Our partners vary from researchers at the School of Engineering through to surrounding hospitals and cancer and medical research institutes. Anyone who is in the immediate vicinity can come along and say, “I need to do this” or “I need to do that”. Or if they don’t know exactly what they want to do, “I have this question, can you answer it?”.

Arcitecta: The Helium Ion Microscopy Node is an impressive piece of machinery. In short, what does it do?

[AB]: In very simple terms it is a powerful microscope. So, it allows us to see things that you can't see with the naked eye – down to the nanometer scale. That’s a billionth of a meter. We’re talking really, really, really small scale things.

Arcitecta: What are we looking at when we reach this microscopic scale; it must be a whole new world in there?

[AB]: A lot of materials engineering and materials research is going further and further down to this sort of scale. As long as it can be put under ultra-high vacuum, we can study it.

We could be looking at how the different grains of steel or aluminum alloys join together and how those metals corrode. Corrosion or what could cause corrosion starts on an incredibly small scale. In the aeronautical context, an engineer wants to know that the blades of a jet engine are going to spin at speeds to keep the plane in the air. Understanding possible defects of the materials is critical from a materials engineering perspective.

We also look at nanostructured materials, things that have a structure on the nanometers scale.

This might look at very complex engineering problems, like how we filter water or potentially blood to remove even the smallest trace of a toxin or toxicant. Cleaning micron-sized bacteria are reasonably easy to filter out, but viruses and heavy metals are much smaller. Looking at these nanostructures we can identify porous small pores to filter those, but let the water or blood through.

We look at cells; red blood cells, white blood cells, virus cells, bacteria cells, and cancer cells. As long as they have been dehydrated and fixed onto a substrate, we can look at them. What we are looking at is their structure and their morphology to determine how certain treatments might destroy a cell or not.

I have looked at a tremendous range of things in my career so far! When I was in the U.K. I looked at an entire ball joint from a knee replacement. The researchers had wanted to understand why the surface had worn down and failed; because it effectively means the patient needs another replacement, which of course is not a pleasant experience.

Arcitecta: The MFCP are obviously creating and managing a lot of research data, can you tell us how you came about Mediaflux as a data management solution?

[AB]: Across the University, we generate tremendous amounts of scientific data and reliably and safely storing this data has become an essential feature of the University’s innovation strategy.

It makes sense to look towards a universal data management solution that can handle all of the data.

We have been working with the University of Melbourne’s Research Platform Services for over 10 years, with a goal to create a trusted research specific infrastructure for use across the University’s research ecosystem. Our goal for the University’s Materials Characterisation and Fabrication Platform (MCFP) was to evolve the way it handles data.

Research institutes around the world use Mediaflux to easily deliver data to offsite storage that is backed up and then use that to actually send the data, or a link to the data, between researchers. This can happen very quickly and easily via an email; scientists do not have to worry about USB drives, viruses and all of the problems that hardware can present. University partners see the added value of state of the art data management.